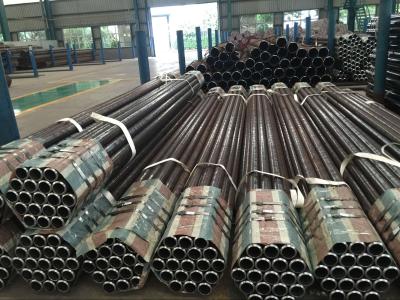

Seamless steel tubes

| Size: | 1/ 2"-24" |

| Nominal wall thickness: | Sch5-Sch160XXS |

| Standard: | ASME B36.10M1996, API, ANSI, GB, SH, HG, MSS, JIS, DIN |

| Material: | ASTM A106 GRB/ A53 GRB/ API 5L GRB/API 5 CT /Q345/A335/ST37/ST52 |

| Certificate: | API ,ISO9001:2008,TUV,SGS,CCS,ETC |

Quality Standard:

ASTM A 53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASTM A519 Seamless Carbon and Alloy Steel Mechanical Tubing

GB/T8162 Seamless Steel Tubes for Structural Purposes

JIS G3441 Alloy steel tubes for machine purposes

JIS G3444 Carbon steel pipes for general structural purposes

JIS G3445 Carbon steel tubes for machine structural purposes

DIN 2391 Seamless Precision Steel Tubes

EN10305 Steel tubes for precision applications. Technical delivery conditions. Seamless cold drawn tubes

EN 10210:Seamless structural steel pipes

Steel Grade:

ASTM A 53: Grade A, Grade B, Grade C, Type F, Type E

ASTM A519: 1010-1045, 4130-4142, 5135

GB/T8162: 10, 20, 35, 45, 16Mn, 12C rMo, 15CrMo, 12C rl MoV

JIS G3441: SCM 415 TK, SCM 418 TK, SCM 420 TK, SCM 430 TK, SCM 435 TK, SCM 440 TK

JIS G3444: STKM 11A, STKM 12, STKM 13, STKM 14, STKM 15, STKM 16, STKM 17, STKM 18

STKM 19, STKM 20

DIN 2391: St30Si, St30A1, St35, St45, St52

EN10305: E235, E355

EN 10210: S235JRH; S275J0H, S275J2H; S355J0H, S355J2H; S275NH, S355NH; S275NLH, S355NLH

Size:

Outer Diameter:Hot finish: 2" - 30",Cold drawn: 0.875" - 18"

Wall Thickness:Hot finish: 0.250" - 4.00",Cold drawn:0.035" - 0.875"

Length: Random Length, Fixed Length, SRL, DRL

Heat treatment:

Annealed: Bright annealed, , Spheroidize annealed

Normalized, Stress relieved, Cold finished, Quenched and Tempered

Delivery Condition : BKS, NBK,BK ,BKW, GBK(+A), NBK(+N), BK(+C)

Packing:Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips

Test:Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield

strength, Elongation), Technical Properties (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc), Exterior Size Inspection.

Mill Test Certificate: EN 10204/3.1B

We have adopted advanced production equipment and technologies to manufacture our seamless steel , erw pipe,spiral steel,galvanized pipe ,oil casing,which can not only improve product quality, but also save raw materials