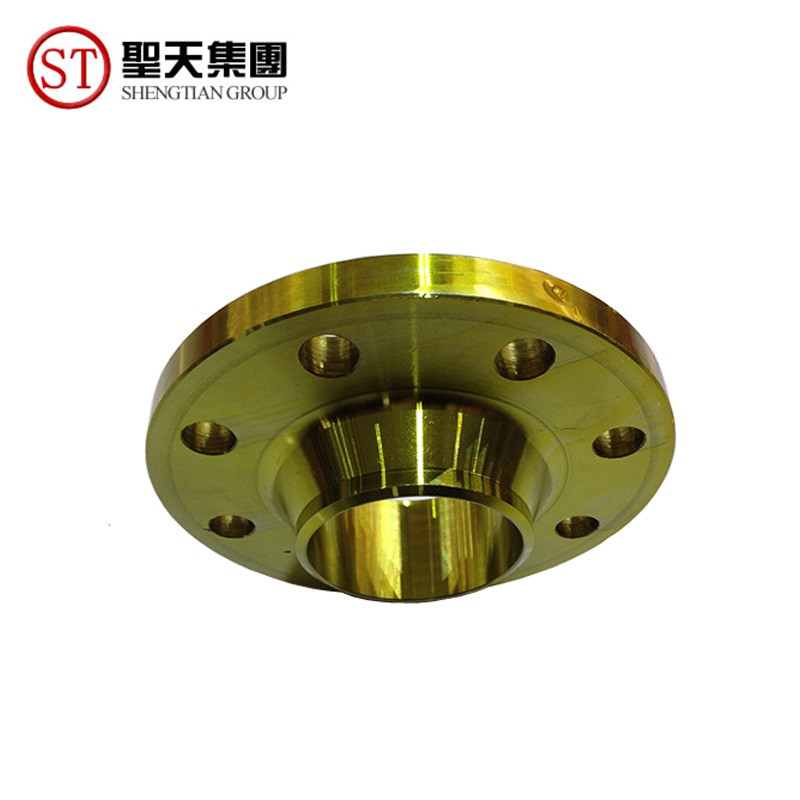

PN1.0 DN65 Cast Steel Flange

| Size: | |

| Nominal wall thickness: | pipe flange standard |

| Radius: | Japanese tube flange standard |

| Bending Degree: | Japanese tube flange standard |

| Material: |

Main pipe flange on international standard has large amount of system, namely, represented by German DIN standard of European tube flange system and represented by the ASME pipe flange standard flange system of America.

1. The European system pipe flange standard

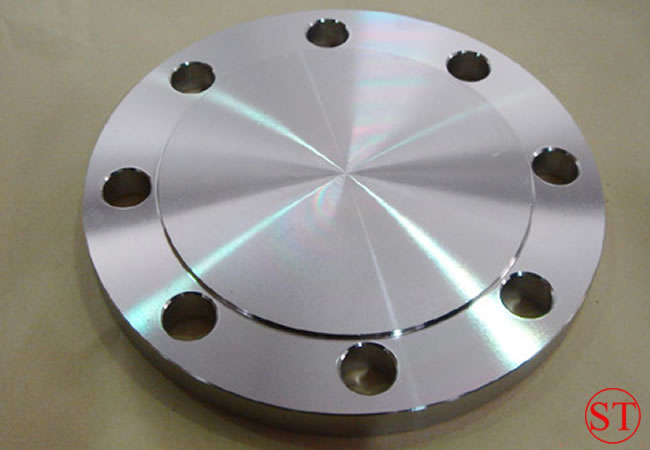

German pipe flange standard nominal pressure for PN1.0 \ PN2.5 \ PN6 \ PN10 \ PN16 \ PN25 \ PN40 \ PN63 \ PN100, the structure of the flange are: plate flat welding, butt welding, overall, loose thread, flange ring set loose tube, flat welding, butt welding loose tube, flange cover eight kinds.Sealing surface are: plane, surface, concave and convex surface, grooved surface and the surface of the o-rings.

2. The American system of tube flange standard

American system mainly refers to the United States (ANSI/ASME B16.5 and ANSI/ASME B16.47) represented by the pipe flange standard.

The nominal pressure rating for Class150 (PN2.0), Class300 (PN5.0), Class400 (PN68), Class600 (PN110), Class900 (PN150), Class1500 (PN260) and Class2500 (PN420)

In addition to the ASME B16.5, in 1990 the United States to MSS - SP - 44 and API 605 two sets is given priority to with large diameter (DN > 600 mm) of the flange standard merged, with A, B two series.

3. The British and French pipe flange standard

4. Japanese tube flange standard

JIS B2220-2004 "steel pipe flanges, as a representative of the Japanese national standards flange, their level of stress for 2 k, 5 k, 10 k, 16 k, 20 k, 30 k and 63 k,